Conveying system

Release time:2018/10/11 Intelligent Logistics Views:4104

Conveying Equipment

Automatic Logistics Warehouse System realizes the automatic transportation of stored unit through conveying system which is able to transport the goods in straight line, curved line as well as up and down. The conveying system consists of pallet conveyor, turnover box conveyor and rail guide vehicle (RGV) etc.

Pallet Conveyor

Taking pallet as unit of stored goods, the pallet conveyor consists of chain conveyor, roller conveyor, lifting and transporting conveyor, palletizer and de-palletizer, reciprocating lift etc.

Turnover Box Conveyor

Taking turnover box as unit of stored goods, the turnover box conveyor consists of roller conveyor, belt conveyor, lifting and transporting conveyor, palletizer and de-palletizer, continuous lift etc.

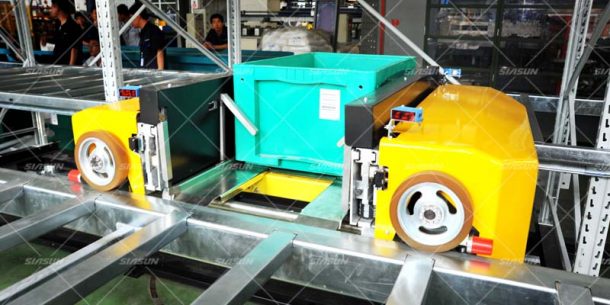

Rail Guide Vehicle (RGV)

Rail guide vehicle, also known as RGV, is a smart robot which could retrieve, transport and place the pallets and turnover box via programming and could communicate with principle computer or WMS to realize the automatic identification, storage and retrieving by integrating with RFID and barcode etc.

Rail guide vehicle could be categorized into circular roller guide and reciprocating line guide based on the mode of motion and into single rail vehicle and double rail vehicle based on the type of rail.

Rail guide vehicle contains frame, driving components, driven pulley components, guide wheel components, conveying system, buffering device, rail system, communication system, control system, inspection system and power supply system etc. Frame is the important component of the vehicle body, which is also the basis for fitting other assemblies. Driving components contain drive motor, shaft and driving pulley. Guide wheel components are mainly to prevent the vehicle from rollover and ensure the vehicle to run in line. Conveying system is mainly divided into chain conveyor and roller conveyor realizing the horizontal transportation in the running direction. Materials of steel and aluminum are basically used in rail system. Communication system, inspection system and control system achieve the purpose of accurate positioning and reliable transportation through the automatic control of vehicle.

Boasting of advantages such as simple structure, convenient maintenance, reliable operation and high efficiency and flexibility as well as competitive price, rail guide vehicle is widely used in logistics conveying systems of every industry.

Lift

Lift is categorized into continuous lift, reciprocating lift and high-speed lift. Transmission path, speed and tempo are set through software. Running speed is controlled by frequency conversion. Equipped with safety device, the lift is able to ensure the safety of labor and goods.

Continuous lift, covering a small area, is mainly to transport the goods in turnover box or paperboard box between floors continuously with the high speed and efficiency. No tempo is wasted.

Reciprocating lift achieves the transportation in vertical and horizontal directions, which could transport the heavy-duty goods up and down smoothly and mainly be used for the transportation of pallets in various sizes.

High speed lift realizes the transportation in vertical and horizontal directions, which could transport the goods in high-speed and mainly be used to work with multi-layer vehicles and stackers.

Pre: Storage rack

Next: Stacker Crane